At Aurora Coop, we adopt four pillars as a practice: excellence of good food, construction of adequate accommodation, efficient transport and specialized professionals. All very well structured to ensure quality at all phases, from the creation to your home. Find out our practices here:

Our Commitments

Ensuring adequate spaces and animal welfare.

Swine

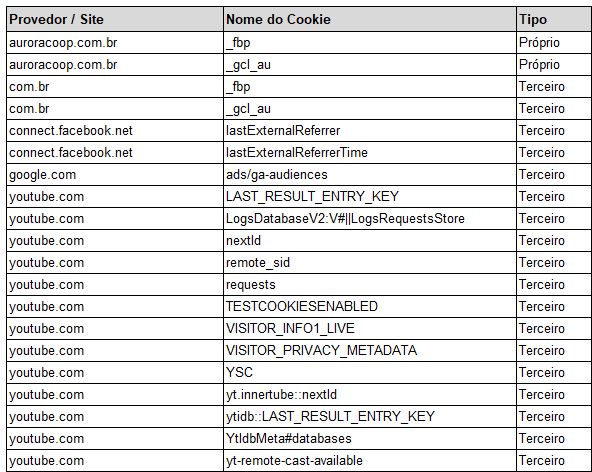

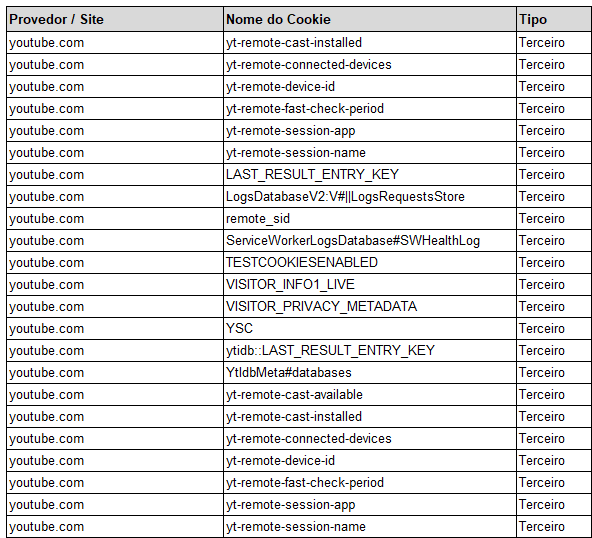

In order to provide animals with a better quality of life and promote their welfare, in accordance with the national and international guidelines of its consumer markets, at Aurora Coop we monitor our production system by means of an internal sense, with the aim of evaluating the progress of the production system in relation to the practices recommended for animal welfare.

We have made progress with the implementation of new and better practices related to the animal welfare policies adopted in their usual breeding managements, especially in relation to what was determined in the last census carried out by Cooperativa, carried out by the technical team of the ten cooperatives that make up the pig production system, and involving over 150 professionals, including technicians, zootechnicians and veterinarians, who are constantly in the field providing assistance to rural producers.

For the year 2025, we reaffirm our commitment to transition from the box gestation system to the collective stall gestation system as a target for the year 2026, reaching 100% transition this year. However, Regulatory Instruction 113, of December 16, 2020, establishes rules and regulations with a deadline of 2045, with Aurora Coop being proactive in this adjustment. In addition, new buildings within the Aurora Coop system from 2021 onwards must comply with the collective gestation standard.

As a result of this commitment at Aurora Coop, we have currently reached the important milestone of 82% (eighty-two percent) of properties with a system for housing pig sows in collective stalls. This is in line with Aurora Coop’s policy of transparency and commitment to animal welfare.

The implementation of collective housing for pig sows allows the animals to express the natural behavior of their species, reducing stress levels and promoting better conditions for the expression of behavioral traits and socialization between the animals.

As can be seen in the 4th Edition of the Pig Watch Report 2023, which monitors the evolution of animal welfare requirements in Brazil’s largest food industries, one of the main issues addressed is the proportion of sows housed in groups during pregnancy in relation to the total number of sows housed. In 2023, Aurora Coop had 85% of its sows housed in collective stalls.

In addition to this important result, which is the result of the work of everyone involved in the production system, it should be noted that we are constantly investing in alternatives to promote greater welfare and quality of life for the animals, which is part of the appropriate behavior for the species, within the Animal Welfare program followed by Aurora Coop.

In order to validate the production system, regular visits are made to producers, with the application of a checklist which, in addition to verifying the progress of the transition from the box system to housing sows in collective stalls, also includes other management practices, such as teeth trimming, tail docking, relevant socio-economic aspects and farm biosafety. The aim is to maintain and evolve the system of animal welfare and good production practices, both of which are of unique importance to the balance and efficiency of production.

To promote this principle, we use resources such as environmental enrichment, which is an important method for promoting a better quality of life for animals. According to our biannual internal census, 83% of the farms that house sows in collective stalls already have environmental enrichment.

In addition, as a form of guidance for technical assistance teams and producers, Aurora Coop has implemented the Pig Sow Collective Gestation Handbook, technical information material containing the principles of animal welfare in collective gestation, followed by Aurora Coop, and recommendations for building and adapting properties, in accordance with the commitment it made.

In addition, all the production manuals have specific guidelines for each operating procedure in animal handling and welfare. These production manuals are passed on to technical teams and producers through training and are revised every two years to comply with current legislation, new market trends and innovations in the area of animal welfare.

In pork production, Aurora seeks progress through research, and the animal’s environment is one of the most important factors in the animal production process. Constant investment is made in environmental improvements to the facilities to promote good animal health and welfare.

With this in mind, in order to provide the animals with a diversified environment, encourage research activities and maintain the species’ natural behavior, minimizing stress levels and agonistic behaviors and stereotypies, Aurora Coop is implementing the practices of using environmental enrichment in all phases of the pig production system, covering, in 2023, in addition to the finishing properties, the implementation in the nursery systems and in the Piglet Production Units.

Learn more about Environmental EnrichmentThe use of environmental enrichment and objects to manipulate the environment in which the animals are housed, such as chains, PVC pipes, plastic gallons, among others, promotes positive effects and behaviors to promote animal welfare, which is also reflected in the production chain and improved pork quality.

In addition, all the pig production manuals have specific operating procedures describing the characterization, manner of use and maintenance of the environmental enrichment objects used on the farms. These production manuals are passed on to technical teams and producers through training and are revised every two years to comply with current legislation, new market trends and innovations in the area of animal welfare.

Poultry

We prioritize adequate space for the birds to express their natural behavior, such as dust bathing, wing flapping and scratching

At Aurora Coop we have adopted the density recommendations of the European Union Directive, considered to be one of the best in the world, with a maximum density of 39 kg/m²:

- 69.42% of the poultry are housed at densities of 29.43 kg/m²;

- 25.05% housed at a density of up to 33.37 kg/m²; and

- 5.45% at a density of up to 38.44 Kg/m².

No bird in our production system is kept in a cage.

70% of broiler farms have conventional, positive pressure aviaries, with natural lighting throughout the day, with at least 8 hours of light a day and at night we have a minimum of 4 hours of darkness, always following the light intensity according to each stage of the bird’s life and the breeding system.

In broiler production we seek progress through research, and ambience is one of the most important factors in the animal production process. There is constant investment in environmental improvements in facilities to provide the animals with adequate thermal comfort through the use of temperature, relative humidity, ventilation, lighting and radiation controllers, among others.

Our aviaries have heating and cooling systems, depending on the time of year, providing the birds with adequate thermal comfort and allowing them to express their natural behavior.

The facility’s maximum and minimum temperatures and humidity are recorded daily in all production systems. These factors directly influence the thermal comfort and welfare of the birds.

To promote the birds’ comfort with enriched environments, we use quality poultry litter at least 10 cm deep, preferably wood shavings, but rice husks are also allowed.

In the production of fertile eggs, 100% of the breeder hens are cage-free and have access to the nest, a necessary tool for exercising their natural behavior.

All of Aurora Coop’s poultry farms are insured and have a Contingency Plan in case of claims.

All poultry farms, depending on their production, implement the practices set out in the Good Production Practices Manuals for Broiler and Breeder Poultry, and have them available for consultation. These materials basically contain guidelines on animal handling and welfare. In addition, each farm has checklists for evaluating the management procedures on the farms.

As of 2020, we will only be using eggs from suppliers that have a cage-free system for 100% of their industrialized products. We maintain our commitment to using only inputs from cage-free hens for the production of our brands’ products, with a confirmatory statement from the supplier. Proof of this is our ranking in the EggLab 2022 annual report, with the transition completed for this issue in 2023.

Dairy Cattle

Aurora Coop and the eight cooperatives affiliated to it in the dairy sector have a technical team with professionals in the fields of veterinary medicine, zootechnics, agronomy, biology and agricultural technicians who help the more than 3,000 producers who supply milk to continuously improve their properties, through various training courses and projects developed in the field.

The production systems used are extensive, semi-intensive and intensive, prioritizing in each system a good human-animal relationship and management care that promotes animal well-being, allowing them to express their natural social behavior.

Dairy farmers enter the Aurora Coop system after passing the Good Agricultural Practices checklist and complying with animal welfare and milk quality standards. This checklist, which is carried out annually, assesses items related to the adoption of good management practices and the use of alternatives that promote animal welfare (water supply in the paddocks, shading, thermal comfort and rest), which directly influence the quality of life of the animals and the people involved in the production system.

Animals that have access to good food, good housing, good health and appropriate behavior are more productive and provide better quality milk. To this end, Aurora Coop, together with its affiliated cooperatives, has training programs for rural producers, which develop rural property in the economic, social and environmental spheres, improving the quality of life of animals and people in the countryside.

One of the Training Programs that develops rural properties is the More Healthy Milk Project, developed by MAPA (Ministry of Agriculture, Livestock and Supply) in 2015 and which has been carried out within Aurora Coop since 2019, benefiting producers in terms of economic profitability, generating a significant evolution in the management, well-being and health of animals, resulting in improved quality of the milk produced.

We have also been developing the Aurora Genetic Model program since 2014, a pioneer in Brazil in using animal genome analysis, which aims to identify points that can be improved in dairy herds. This program has already improved the animals in various aspects, especially in the feet and legs area, which directly influences the ease of movement and the animals’ well-being. There has also been an improvement in the udder area, milk composition and somatic cell count, resulting in a herd with a high level of animal well-being, which is healthier, longer-lived and more productive.

We believe that people are the most important resource in the evolution of the milk chain, which is why our technicians undergo frequent training, and in 2021 and 2022 we carried out training in the following areas:

- Nutritional Guidance: aimed at forage planning for farms and technical guidance on a balanced diet that meets the requirements of each animal category, in order to maintain their well-being, health and productivity.

- Milking Equipment Maintenance: through the acquisition of pulsographs and flow meters that enable the technical team to evaluate the equipment’s operating parameters, making the necessary adjustments to provide the animals with complete milking without discomfort, promoting their well-being.

- Facilities: guidance on the construction and sizing of facilities that allow for resting comfort, ease of movement and access to food and water; use of fans and sprinklers that provide thermal comfort, to promote animal well-being.

- Mastitis Treatment and Prevention: to provide knowledge about the bacteria that cause mastitis, and how to prevent and treat each agent. To maintain good health and promote the well-being of the animals, reducing the impact of production and increasing milk quality.

Because mastitis is extremely important for the well-being of dairy cattle and for the production and quality of the animals’ milk, we conduct a weekly antibiogram test in our own microbiology laboratory, which allows for a precise diagnosis of the infectious agent, enabling the technical team to act more quickly and assertively in the field, considerably reducing the use of antimicrobials and reducing interventions in the animals’ routine.

At Aurora Coop, through these actions, we are boosting not only milk production, but also the quality of life of animals and people in the countryside, by providing a product of unique quality, a premium product with a very rich nutritional value.

Management Practices

With technical studies and adaptations, we have reduced and abolished some of the management practices used in the processes. These include:

- Collective Gestation: We reiterate our commitment to transition from the stall-based gestation system to the collective gestation system by the year 2026, achieving 100% transition that year.

- Group Housing and early mixing (post-insemination): Starting in 2025, all new facilities intended for swine breeding must mandatorily adopt the “Group Housing and early mixing” system as a constructive and functional standard.

- Surgical castration: Aurora Coop only chooses to adopt immunocastration, as it is less invasive for the animals.

- Teeth trimming: We don’t allow teeth to be cut; we always prioritize the best management practices. In accordance with our pig production manual, we only trim piglets’ teeth when necessary, in cases where they compromise the sow’s mammary system or the piglets’ faces, thus ensuring that this practice is carried out ethically and with the least possible impact on animal welfare.

- Tail docking: this practice is only carried out on piglets and follows the technical procedures recognized worldwide by the Health Code of the WOAH (World Organization for Animal Health). This management is necessary to maintain animal welfare. Aurora Coop recommends and guides the entire production system, in accordance with Regulatory Instruction 113, of December 16, 2020, so that cutting is only carried out in the final third of the tail and up to the third day of the piglets’ lives.

- Notching: We are committed to replacing animal dents from 2026, with a target of 30% replacement per year, adopting authorized forms of marking that respect animal welfare

- Beak trimming in poultry: We do not carry out the practice of beak trimming in poultry farming at any stage of production.

Our Practices

We believe in transforming the world into a fairer, happier and more balanced

place with better opportunities for everyone.

If you have any questions about our processes, talk to our team of experts.